MediShield™ Coating Products

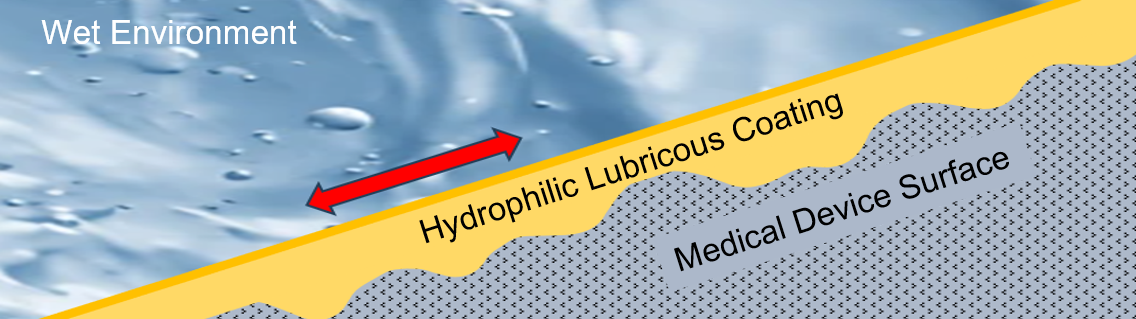

Hydrophilic Lubricious Coating

Engineered to provide high-performance lubricity for medical devices, enabling them to glide smoothly over tissues or other device surfaces in wet or aqueous environments. The coating reduces friction, enhances maneuverability, and supports safer, more efficient clinical procedures.

GET MORE INFO

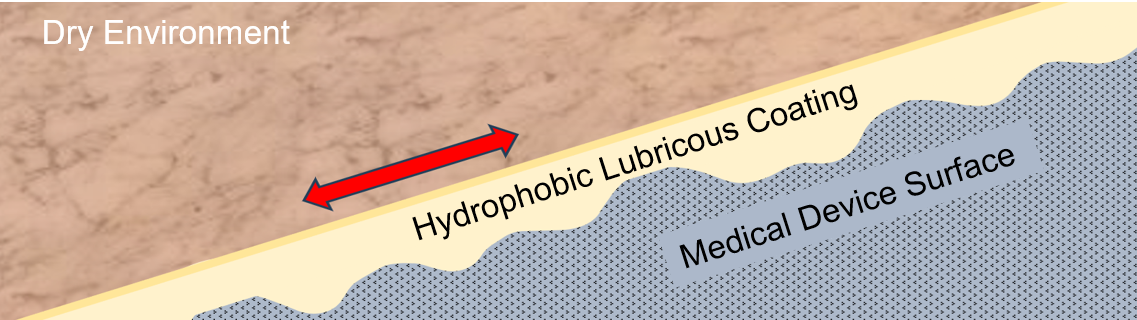

Hydrophobic Lubricious (MSLIP) Coating

Engineered to provide exceptional dry lubricity for medical devices that must slide smoothly against another surface - for example, a tube moving within an over-tube. Its performance is comparable to PTFE coatings, while offering the added benefit of being completely PFAS-free.

GET MORE INFO

Superhydrophilic Coating

Engineered to transform medical device surfaces by dramatically increasing their wettability. By promoting rapid and uniform water spreading, the coating enhances visualization, fluid management, and device performance across a wide range of clinical applications.

GET MORE INFO

Superhydrophobic Coating

Engineered to repel water and bodily fluids by creating an ultra-low surface-energy

barrier that keeps devices clean, dry, and resistant to contamination.

Biocompatible Coatings

Designed for mitigating adverse in vivo reactions of implanted medical devices and biosensors, MediShield™ Biocompatible Coatings resist protein binding and cell attachment. They can be applied on a wide variety of materials and devices. They are also fully compatible with biosensors such as glucose sensors.

GET MORE INFO

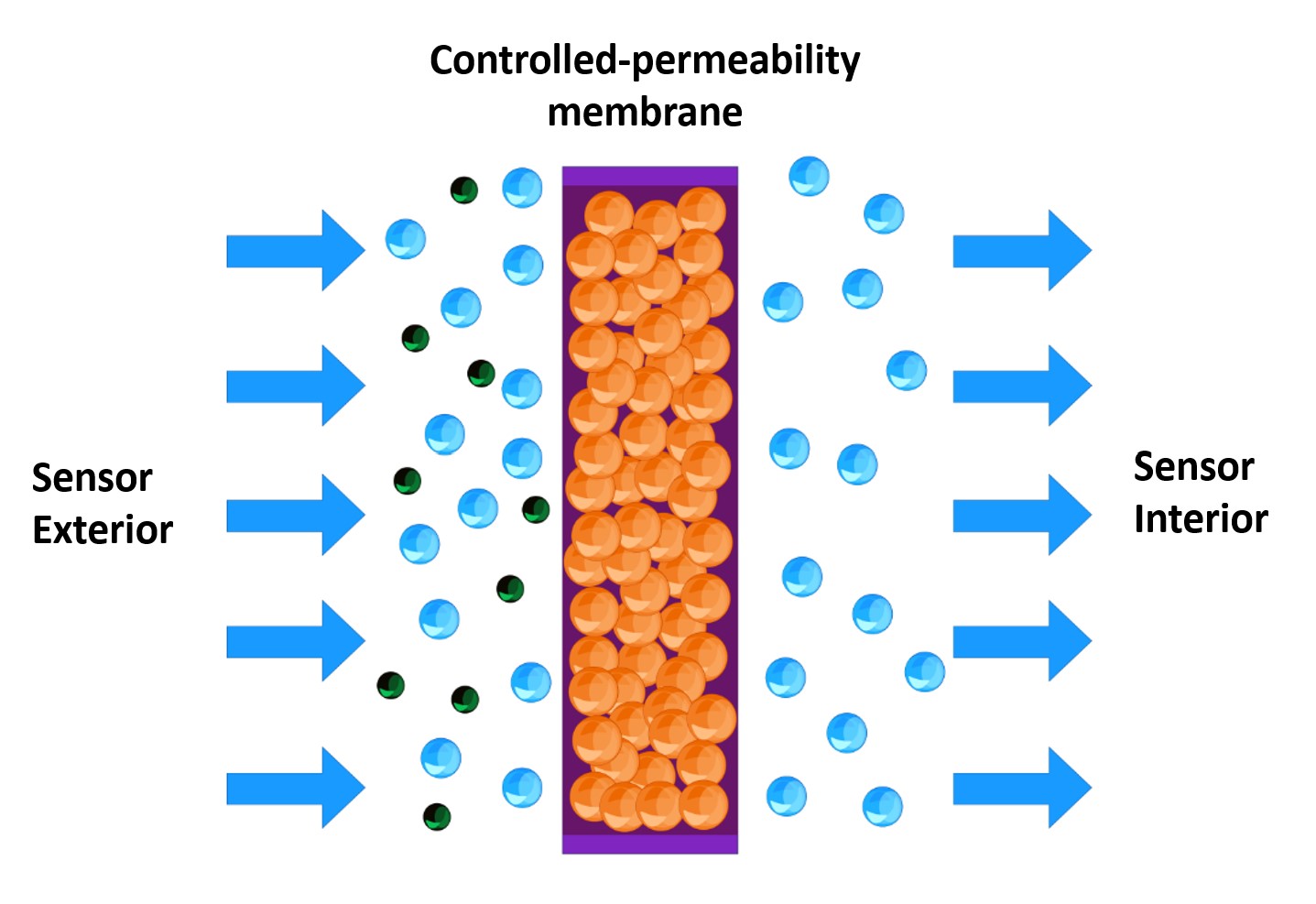

Diffusion-Limiting Membrane Coatings

Designed for biosensor applications, MediShield™ Diffusion Limiting Membrane Coating can be customized to control the permeability of certain molecules. One example is Glucose Limiting Membrane (GLM) coating, which is used to improve the accuracy of glucose sensors.

GET MORE INFO